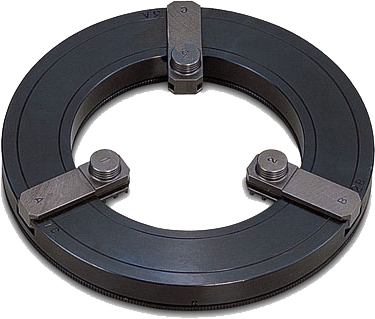

Jaw Boring Fixtures (3 - Jaws) TL type

The Master Jaw Boring Fixtures (TL Type) provides continous adjustment for accurate position to reduce the abrasion of soft jaws.

Small sizes soft jaws can be made easily using the Master Jaw Boring Fixtures. With anticlockwise lock, the machining field can be easily extended.

Features :

- Quickly bore jaws in a single operation with no plugs or rings

- Suitable for CNC lathes

- Easy to attach. No tools needed

- Jaws are bored at same clamping pressure used to hold part for higher accuracy

- Cover chuck sizes from 5" to 12"

|

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

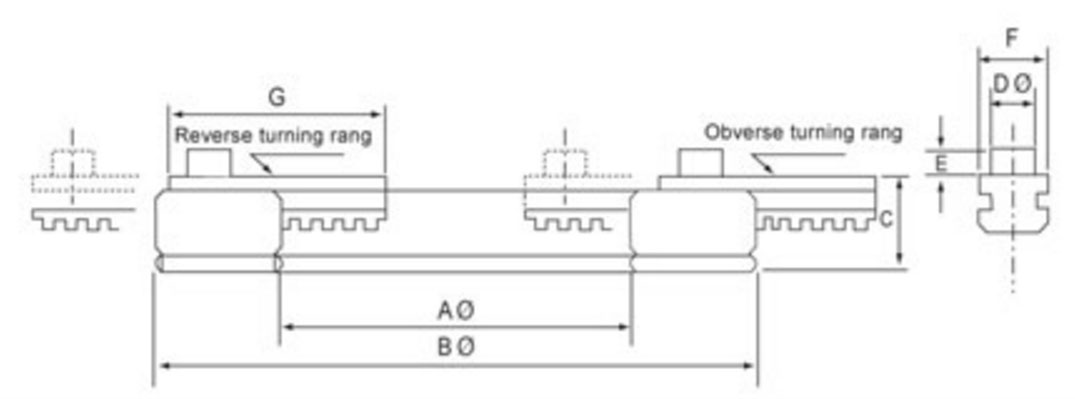

| Part No | A | B | C | D - E | F-G | Jaw Stroke Each |

Max Gripping Kgf |

Max Speed RPM |

Weight | Matching Chuck |

| MBR-100 | 100 mm (3.94 inch) |

170 mm (6.70 inch) |

26 mm (1.02 inch) |

13 - 7 mm (0.5 - 0.28 inch) |

19-61 (0.75- 2.40 inch) |

7.4 |

1,500 | 800 |

2.7 kg (5.95 lbs) |

5", 6", 8" |

| MBR-125 | 125 mm (4.92 inch) |

200 mm (7.87 inch) |

26 mm (1.02 inch) |

16.3-8 (0.64 - 0.32 inch) |

19-61 (0.75 - 2.40 inch) |

7.4 |

1,500 |

700 |

3.5 kg (7.72 lbs) |

6", 8", 10" |

| MBR-160 | 160 mm (6.30 inch) |

248 mm (9.76 inch) |

31 mm (1.22 inch) |

18.3-8 (0.72 - 0.32 inch) |

24-80 (0.94 - 3.15 inch) |

8.5 |

1,750 |

600 |

5.6 kg (12.35 lbs) |

8", 10", 12" |

Operation Process :

1. Set the jaw to the correct position

2. Adjust the Jaw Boring Fixtures to fit the bolt holes, and turn opposite direction of the chuck clamping force

3. Lock the chuck to clamp the Jaw Boring Fixtures.

4. Machining the required size

5. Unlock the chuck and remove the Jaw Boring Fixtures